MIL-DTL-29451B(MC)

Manufacturing requirements - Continued.

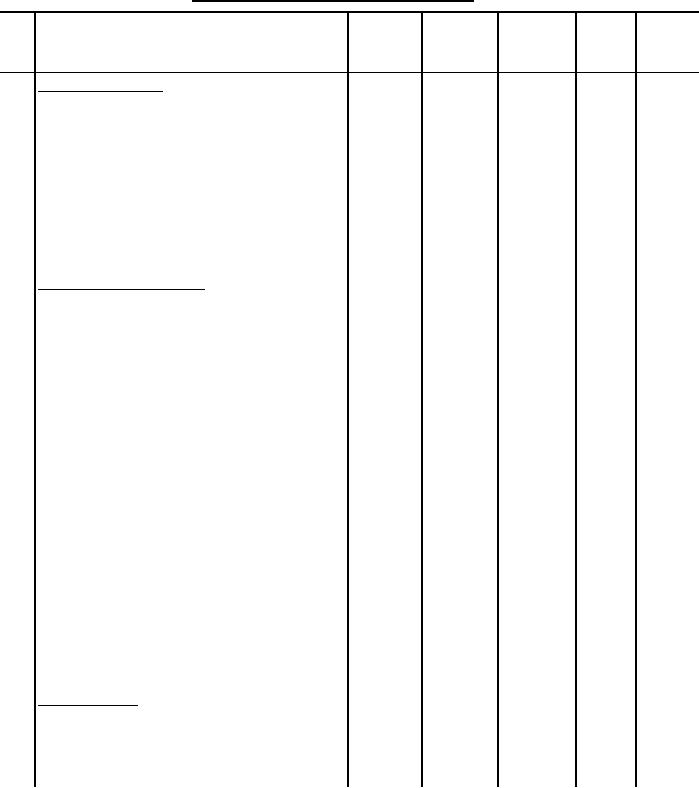

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

Make knit cuffs.

5

(cont'd)

b. Press the seam open with

a heated

steam iron and fold the cuff

in half

on the length. The finished

cuff

length shall be 2-1/2 inches

± 3/16

inch.

c. Pre-knitted cuffs may be used in

lieu of piece goods, provided

established dimensions are adhered

to.

Make shoulder straps.

6

a. The shoulder strap shall be made

from two plies of basic material and

one ply of fusible interlining.

b. Position the fusible interlining

material on the underside of the top

strap and fuse as specified in 3.6.2.

c. Position top strap and under

301

SSe-2

10-12

70

70

strap face to face so that when

(a)

shoulder strap is stitched and

turned, the fusible interlining will

be on the underside of top strap.

Join all plies along the side edges

and the pointed end with a 1/4 inch

seam.

d. Trim and turn the shoulder strap,

301

SSe-2

10-12

70

70

forcing out the edges and pointed

(b)

end. Top stitch the shoulder strap

1/8 inch from the outer edge. The

shoulder strap shall be 2-1/4 inches

wide at the armhole and 1-3/4 inches

wide at the neck.

7

Make sleeves.

a. Join the underarm seam of the

301

SSa-1

10-12

70

70

sleeve with a 3/8 inch seam.

b.

Press the underarm seam open.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business