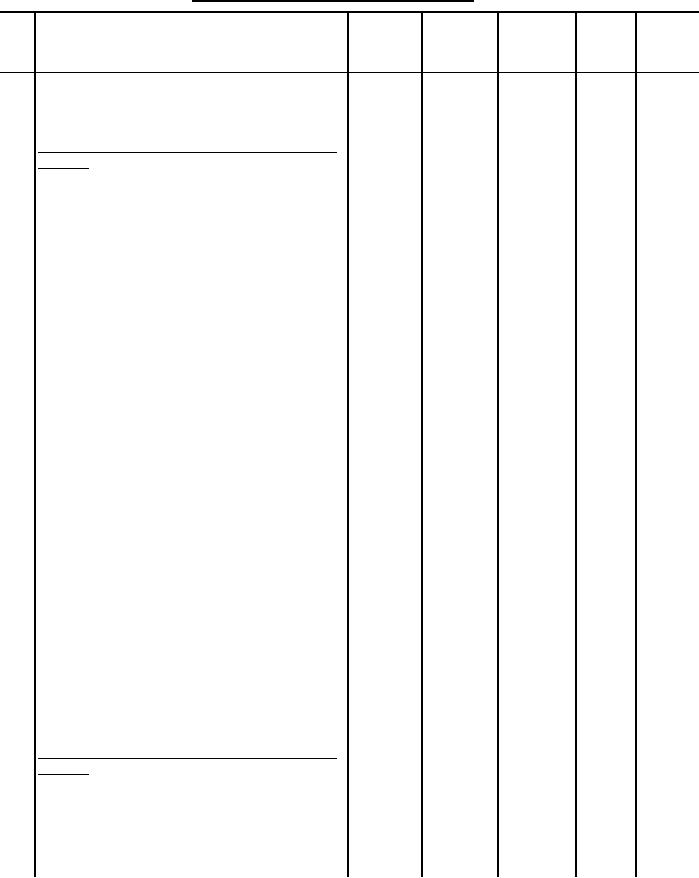

MIL-DTL-29451B(MC)

Manufacturing requirements - Continued.

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

b. The joining seam shall be pressed

toward the side seam with a hot steam

iron or press.

14 Assemble inside pocket on lining and

facing.

a. The inside pocket shall be made

of one piece of polyester twill cloth

with a facing of rayon lining at the

horizontal double piped pocket

opening.

b. Position the rayon facing on the

301

LSd-1

10-14

A

A

pocket material with notches

(each

matching. Turn under the top and

turned

bottom edges, respectively, of the

edge)

facing and seam the facing to the

SSa-1

10-12

pocket 1/16 to 1/8 inch from the

(each

folded edges. Selvage edge need not

selvage

be turned under.

edge)

c. Sew the combination label to the

301

SSa-1

10-14

A

A

outside of the right pocket facing,

centered, 1/2 inch below pocket

opening, with a single row of

stitching 1/16 inch from each edge.

Stitch the label to pocket 1/16 inch

from each edge.

d. Mark the right facing and the

front lining, with the pocket marker

furnished, for the position of the

pocket opening.

e. Position the pocket at the mark

with the pocket facing next to the

lining material. Place the polyester

twill stay piece on the underside of

the lining, with the diagonal

extension of the stay extending to

the armhole edge of lining.

14 Assemble inside pocket on lining and

facing. (cont'd)

f. Stitch the pocket to the lining

301

SSv-2

10-14

A

A

and facing through the stay piece

with one row of stitches 3/16 to 1/4

inch on each side of the mark for the

pocket opening.

15

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business