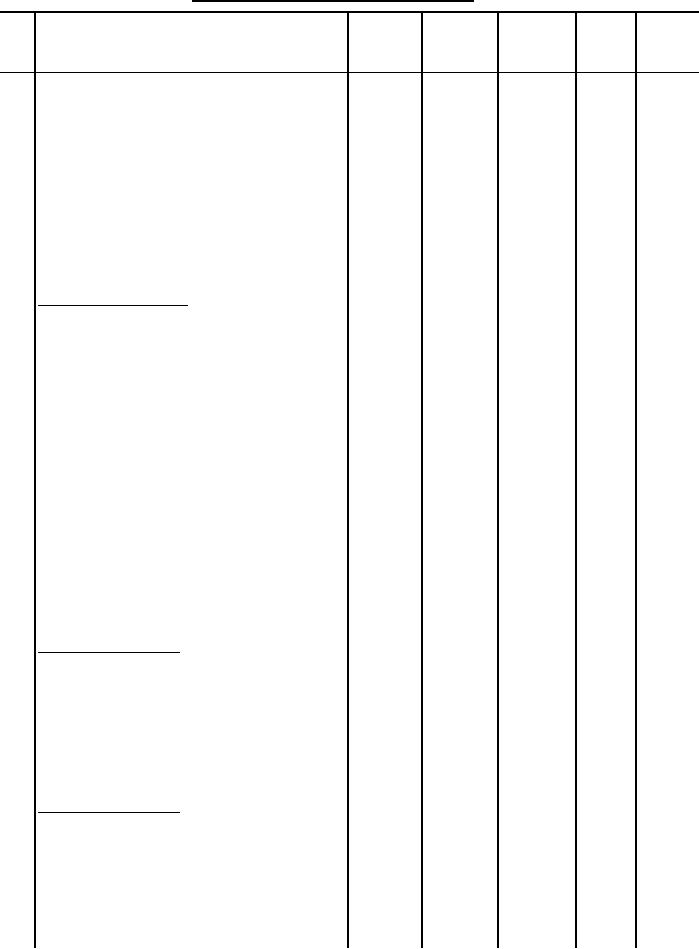

MIL-DTL-29451B(MC)

Manufacturing requirements - Continued.

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

b. Overedge stitch the raw edges of

503

EFd-1

8-10

70

70

the front and back shoulder linings

or

together.

504

-or-

c. The front and back shoulder

515

EFd-2

8-10

70

70

linings may be seamed and overedged

or

together in one operation.

516

or

517

or

518

18 Make sleeve lining.

a. Join the sleeve underarm seam

301

SSa-1

10-14

70

70

with a 3/8 inch seam.

or

401

b. Overedge stitch the raw edges of

503

EFd-1

8-10

70

70

the underarm seam together.

or

504

-or-

c. The sleeve underarm may be seamed

515

EFd-2

10-14

70

70

and overedged together in one

or

operation.

516

or

517

or

518

d. The sleeve seam shall be pressed

toward the back with a hot steam iron

or press.

19 Set sleeve lining.

a. Position the respective sleeve

301

SSa-1

10-12

70

70

lining to the armhole lining and seam

or

with a 3/8 inch seam.

401

b. Overedge stitch the raw edges of

503

EFd-1

8-10

70

70

the sleeve and armhole together.

or

504

-or-

19 Set sleeve lining.

(cont'd)

c. The lining sleeve and armhole may

515

EFd-2

10-14

70

70

be seamed and overedged together in

or

one operation.

516

or

517

or

518

18

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business