MIL-DTL-82161C(MC)

Manufacturing requirements - Continued.

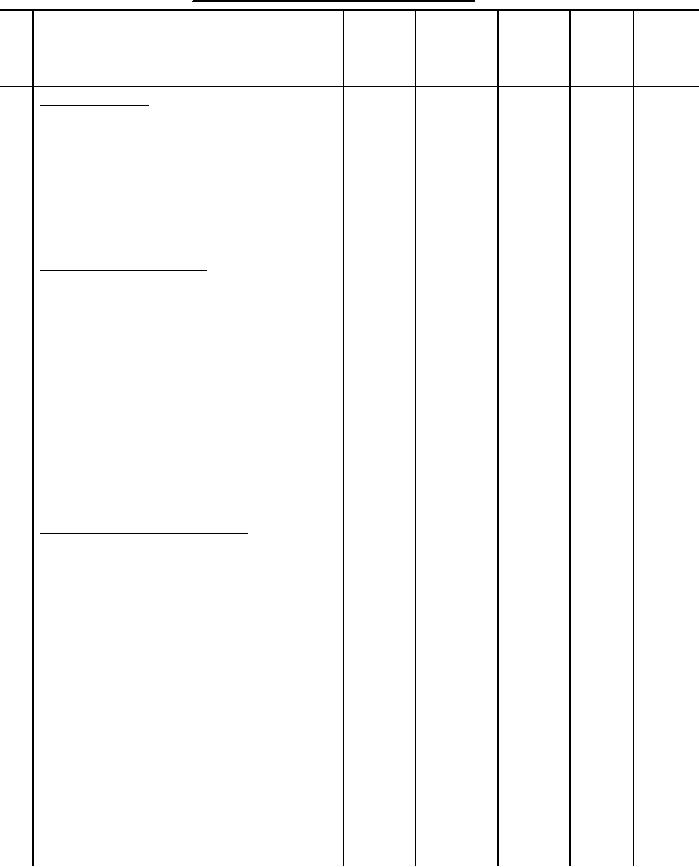

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/I

NDL

LPR

N

15

Join outseams.

(cont'd)

a. Join the outseam with a 3/8

301

SSa-1

12-16

A

A

inch seam, matching the notches as

or

(b)

indicated by marks on the patterns.

401

b. Spread open the outseams from

top edge of trousers to bottom and

press smooth and flat with a heated

pressing iron or pressing machine.

16

Attach ornamentation.

Finished appearance. Ornamentation

shall be centered over the outseam

on the trousers from top edge of

trousers to bottom edge of legs,

with the top end to finish in the

waistband seam. The ornamentation

shall be securely and uniformly

stitched, properly positioned and

shall finish without distortion.

a. Stitch the ornamentation to the

301

SSas-4

12-16

A

A

trousers, from top to bottom 1/16

(b)

(silk

(silk

to 1/8 inch from each edge of

)

)

braid.

17

Sew waistband to trousers.

Finished appearance. The waistband

shall be seamed to the trousers

smoothly and neatly without

fullness, gathers, or pleats.

a. The waistband shall be made of

one ply of basic material.

b. Seam waistband to trousers 3/8

301

SSa-1

12-16

A

A

inch from edge.

c. The raw right front ends of the

waistband shall extend 1/4 to 3/8

inch beyond the front edge of the

right fly. The left front ends of

the waistband shall finish even

with the back edge of the left fly.

The raw right and left back ends of

the waistband shall finish even

with the edges of the back.

16

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business