MIL-DTL-28936B(MC)

TABLE I.

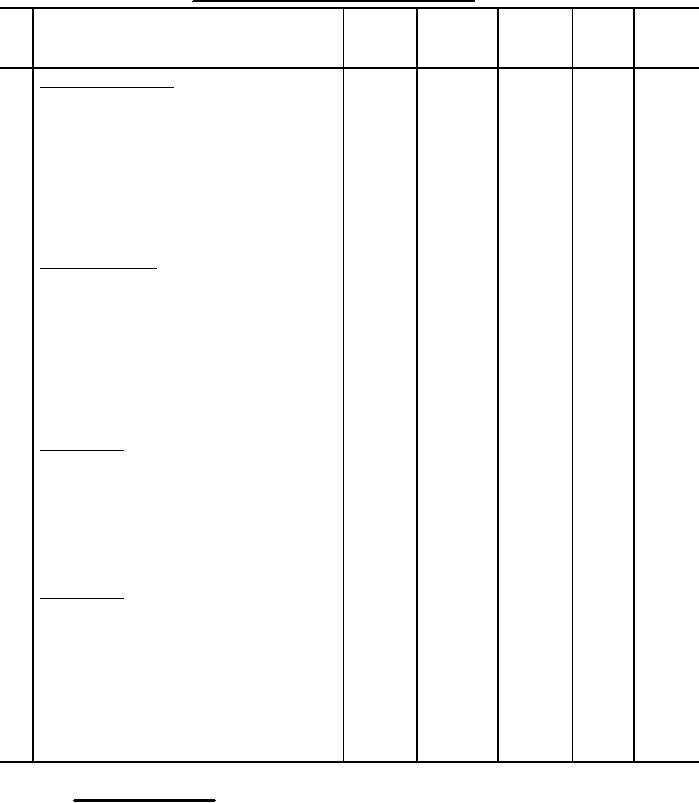

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

Make buttonholes.

17

(cont'd)

c. The buttonholes shall be well

worked over gimp to fit the 22-line

button. The gimp shall be pulled

through to the underside. The

purling shall be on the outside.

d. Securely bartack the end of

Bartack

21 per

40

40

each buttonhole and trim the ends

bartack

of the gimp.

18

Attach buttons.

Finished appearance. The buttons

shall be properly attached/aligned

with the buttonholes to secure a

smooth closure without bulging or

fullness.

a. Insert the buttons through the

eyelets and attach with rings or

toggle pins.

19

Clean vest.

a. Trim all ends of stitchings and

remove all loose threads from the

vest.

b. Remove all spots, shade

tickets, and stains from the vest

without injury to the vest.

20

Press vest.

Finished appearance. Pressing

shall be done with a heated

pressing machine of a type suitable

to obtain the required shape and

appearance in accordance with good

manufacturing practice.

a. Press the entire vest removing

all wrinkles.

3.6.2 Shade marking. The component parts of the vest shall be

shade marked to insure a uniform shade throughout the garment.

Any method of shade marking may be used except:

a.

Corrosive metal fastening devices.

b.

Sew-on shade tickets.

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business