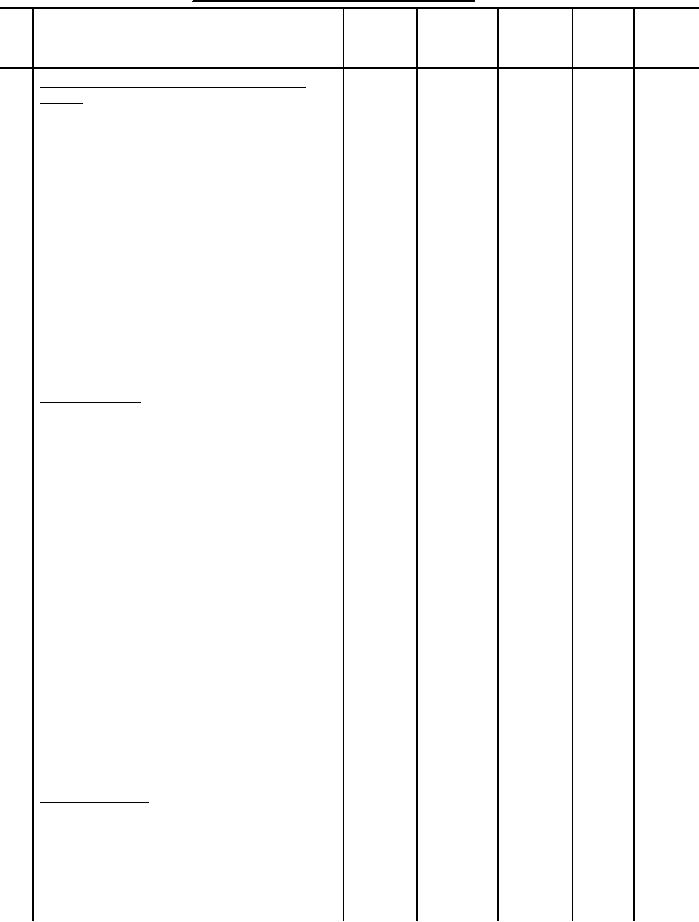

MIL-DTL-28936B(MC)

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

Join facing-lining to front with

11

tapes. (cont'd)

b. Join facing-lining to the front

301

SSab-1

12-16

40

40

with a 1/4 inch seam with the stay

tape on the inside of the front 1/8

inch from the edge and caught in

the stitching. The line of

stitching shall extend from the

ends of the neck extension, along

the front and bottom edge, to the

side edge. Continue closing and

taping the back edge of the front

and facing, leaving an opening

between the notches in the armhole

for turning. The stay tape is not

required along the right front

where the eyelet reinforcement stay

is located.

12

Finish front.

Finished appearance. Fronts shall

finish smooth and flat without

distortion. The edge stitching

shall be uniform width without

twisting, pleating or puckering.

a. Edgestitch the vest along the

301

SSa-1

12-16

40

40

armhole, top, front and bottom

edges. The edge stitching shall be

1/16 inch from all edges.

b. Press the edges of lapel, top,

front and bottom edges of vest with

a heated pressing machine, removing

the fullness. Turn lapel back and

crease along the breakline smooth

and flat.

c. Tack the upper and lower

301

SSa-1

12-16

40

40

rounded corners of the lapel to the

fronts, through all plies, in line

with the edge stitching for a

distance of approximately one inch.

13

Attach slides.

a. Attach a slide to each bottom

301

SSa-1

12-16

40

40

side edge of the vest front by

inserting the end into the first

loop of the slide for 1/2 inch and

topstitch to the inside front with

a 1/16 to 1/8 inch stitch.

12

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business