MIL-DTL-28936B(MC)

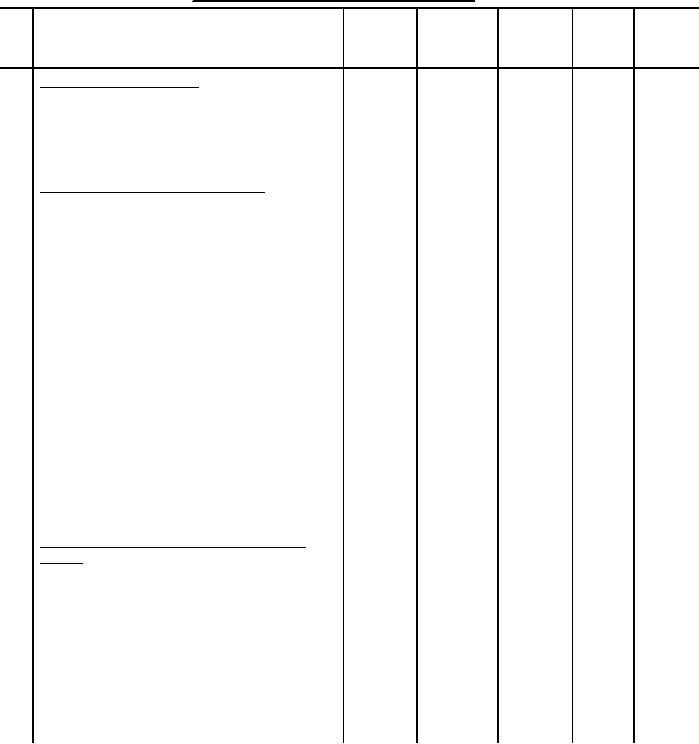

TABLE I.

Manufacturing requirements - Continued.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

9

Make eyelet opening. (cont'd)

c. Stitch the back raw edge of

301

SSa-1

12-16

40

40

lining to the front edge of eyelet

stand with 1/8 inch seam. Trim

excess lining if necessary.

Make eyelets in right front.

10

Finished appearance. The eyelets

shall be worked with the purling on

the outside of the front and shall

finish with 1/8 inch diameter

opening. All stitches shall be

securely caught in the fabric.

Eyelets shall be 5/8 inch from the

front edge and evenly spaced.

a. Mark location of four outlets,

(using the marker) in right front

for removable buttons to properly

align with eyelet buttonholes in

left front, in accordance with

marks on the patterns.

b. Make an eyelet at each mark on

Eyelet

22 min

40

40

the right front, through front and

per

reinforcement stay positioned on

eyelet

the underside of the front.

11

Join facing-lining to front with

tapes.

Finished appearance. The facings

and the fronts shall be joined in

such a way to produce smooth flat

seams without pleats, puckers or

gathers in the vest.

a. Position facing-lining on the

outside of the respective fronts,

with the upper edge of neck

extension and front edges even.

11

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business