MIL-DTL-28936B(MC)

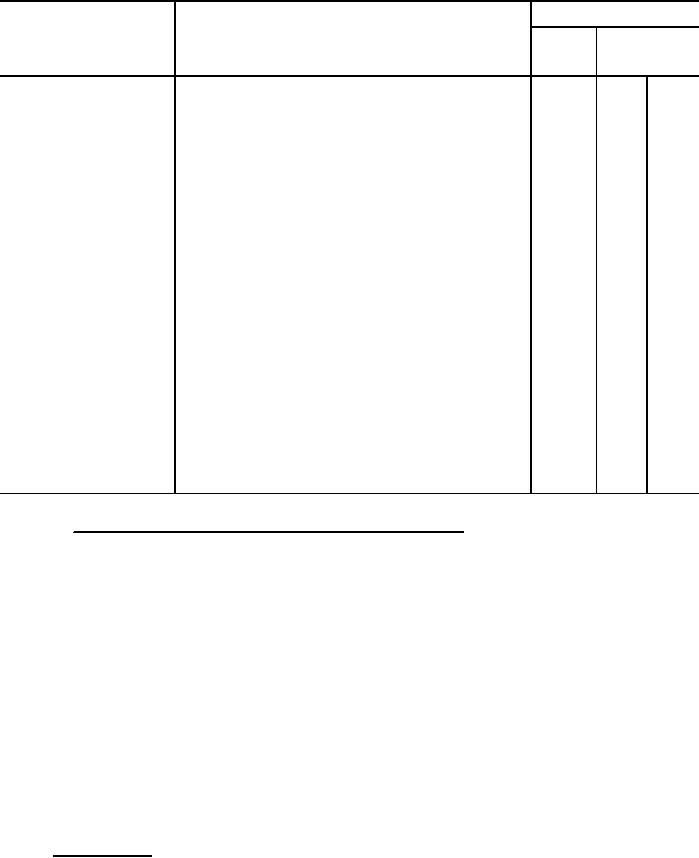

Classification

Examine

Defects

Major

Minor

A

B

Front and

e. Facing exposed on left front

242

bottom edges

edge affecting appearance

(cont'd)

(score only when clearly

noticeable and the condition

exists along major portion of

seam).

f. Bottom corner of one or both

126

fronts poorly shaped, affecting

appearance.

Front facings

a. Short, tight or twisted

127

causing excessive fullness or

twists on front.

b. Facing long, causing bottom

128

corner to curl up.

Identification

a. Omitted.

129

label

b. Incorrect or illegible.

243

c. Not stitched on four sides.

323

4.4.4 Bond strength of fusible interlining. The strength of the

bond of the fusible interlining to the outer fabric shall be

tested once every four hours as follows at each fusing press to

determine that adequate fusing is being obtained. Prepare a test

sample by fusing the fusible specified under the same fusing

conditions to be used for the manufacturer of the vest.

Determine the bond strength of the test sample with a commercial

string scale (see 6.6). If the bond strength on any test sample

is less than 22 ounces per inch of width, the fusing conditions

shall be corrected and the bond strength test shall be repeated.

Those units represented by this test shall be fused and retested

again. If they fail, they shall be rejected.

5.

PACKAGING

5.1. Packaging. For acquisition purposes, the packaging

requirements shall be as specified in the contract or order (see

6.2). When actual packaging of material is to be performed by

Department of Defense (DoD) personnel, these personnel need to

contact the responsible packaging activity to ascertain requisite

packaging requirements. Packaging requirements are maintained by

23

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business