MIL-DTL-43335G

STITCHES

THREAD

SEAM

BOBBIN/

PER

STITCH AND

INCH

NEEDLE

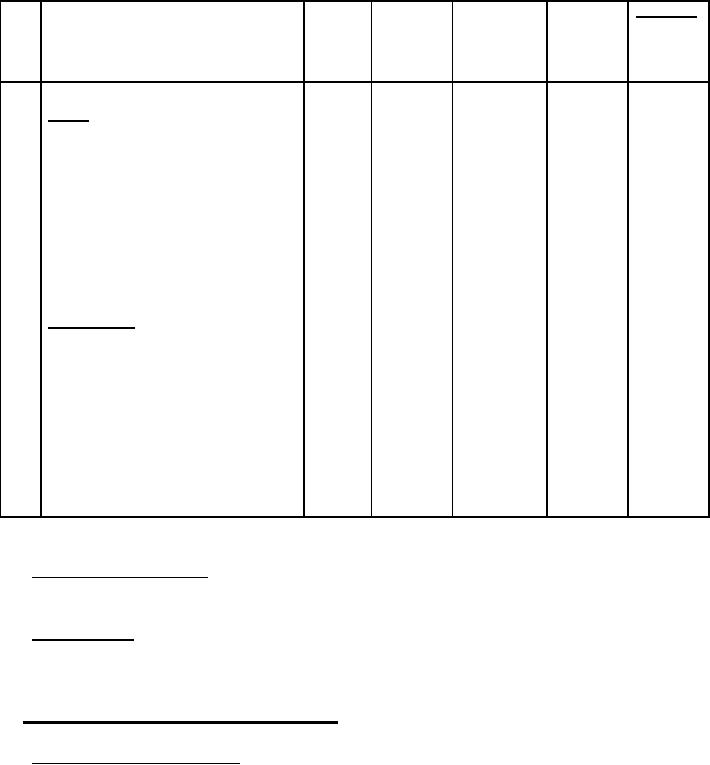

MANUFACTURING OPERATION

TYPE

STITCH

LOOPER

No.

REQUIREMENTS

TYPE

6.

Label.

The combination identification-

301

8-12

B

B

instruction label shall be

positioned on the top side of the

liner in the corner indicated on

figure 1, 2, or 3 and stitched on

all four sides not more than 3/16

7.

inch from edges of label.

Clean liners.

a. Trim all thread ends to ¼ inch

maximum length.

b. Remove all spots and stains.

c. Fold and prepare for packing.

3.6 Finished Measurements. The measurements of the finished liner shall be as specified on

figure 1, 2, or 3.

3.7 Workmanship. The finished liner shall conform to the quality of product established by this

specification. The occurrence of defects shall not exceed the applicable acceptable quality

levels.

4. QUALITY ASSURANCE PROVISIONS

4.1 Responsibility for inspection. Unless otherwise specified in the contract or purchase order,

the contractor is responsible for the performance of all inspection requirements (examinations

and tests) as specified herein. Except as otherwise specified in the contract or purchase order,

the contractor may use his own or any other facilities suitable for the performance of the

inspection requirements specified herein, unless disapproved by the Government. The

Government reserves the right to perform any of the inspections set forth in this specification

where such inspections are deemed necessary to ensure supplies and services conform to

prescribed requirements.

9

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business