MIL-DTL-29451B(MC)

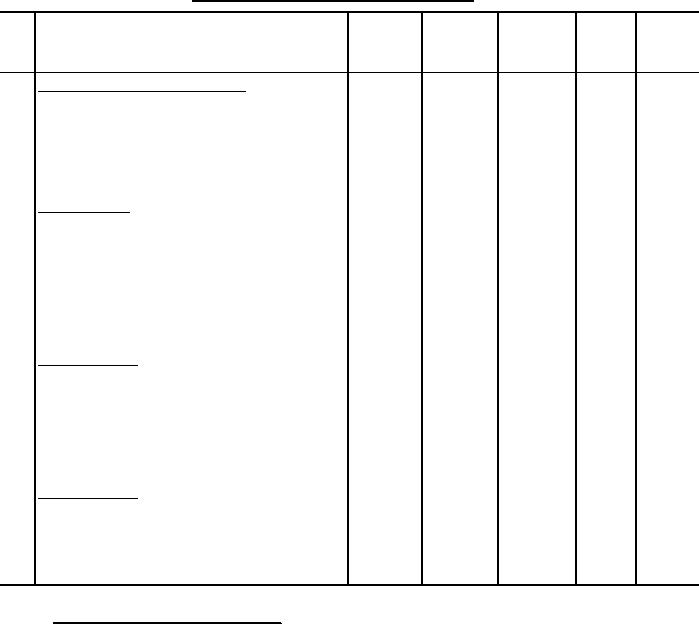

Manufacturing requirements - Continued.

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

32 Mark and make buttonholes.

a. Mark and make one horizontal 5/8 Button-

52-54

inch eyelet end, taper-bar buttonhole

hole

stitches

to fit a 24 line button, 3/4 inch

per

from the pointed end and centered in

button-

each shoulder strap.

hole

33 Sew buttons.

a. Sew one button on each shoulder

301

14-16

to correspond with the buttonhole in

or

the shoulder strap. The stitching

101

20-22

shall go through all plies of fabric

or

and lining but shall not distort the

Hand

4-6

shoulder.

per

button

34 Clean jacket.

a. Trim all thread ends and remove

loose threads from jacket.

b. Remove all spots, stains and

shade tickets without damage to the

fabric.

35 Press jacket.

a. The jacket shall be pressed

throughout with a heated steam iron

or pressing machine. All marks shall

be removed from the jacket.

3.7. Finished measurements. Finished measurements of jacket

shall be as listed in Table II.

22

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business