MIL-DTL-29451B(MC)

Manufacturing requirements - Continued.

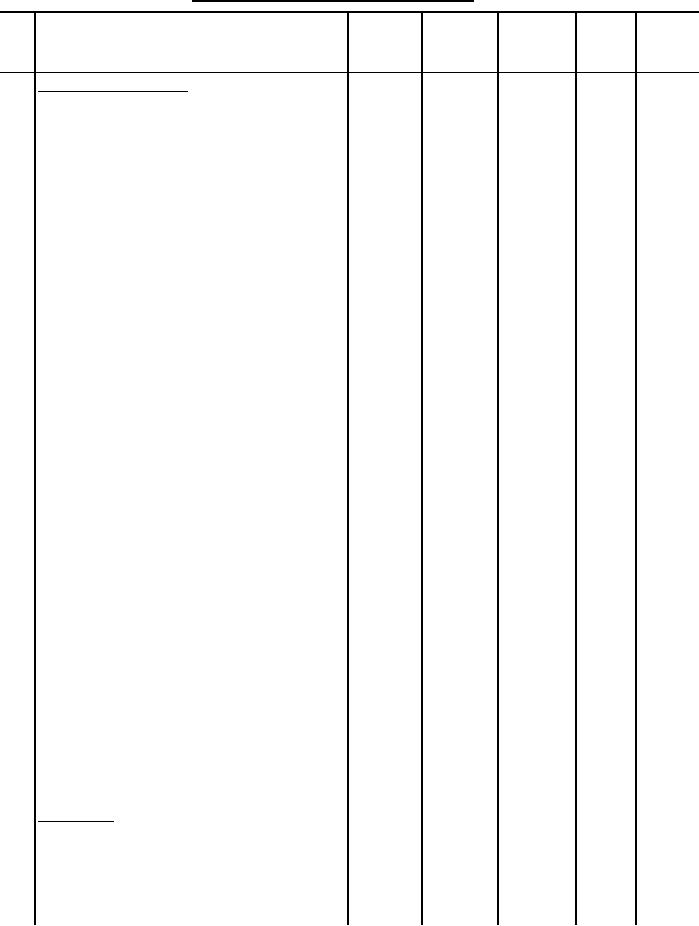

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

9

(cont'd)

Make slash pockets.

g. Position the top welt on the

301

SSa-1

10-12

70

70

outside of fronts with the mark, and

with the folded edge of the welt

toward the back. Position one ply of

pocketing over the welt with the raw

edges even and notches matching.

Seam the pocketing through all plies

1/4 inch from the raw edge.

h. Position the bottom welt and

301

SSa-1

10-12

70

70

pocketing at the pocket mark and

follow the same operation as 9.f.

i. Cut the opening for the pocket.

Tongue notch the corners.

j. Turn the pocketing through the

opening to inside.

k. Raise stitch the bottom lower

301

LSg-2

10-12

70

70

(bottom) welt through the front and

(b)

the pocketing with a single row of

stitching 1/16 inch from the edge.

l. Fold the top welt over the inside

welt.

m. Sew tongues at the corners to the

301

SSa-1

10-12

70

70

welts on the inside with a single row

of stitching.

n. Raise stitch the seam joining the

301

LSq-2

10-12

70

70

top welt and the end of the opening

(b)

through the pocket with a single row

of stitching 1/16 inch from the edge.

o. Stitch around the pocketing with

301

SSa-1

10-12

70

70

a single row of stitching 1/2 inch

from the raw edge.

p. Secure the corners of each end of Bartack

28

the pockets at the base of the tongue

stitches

at the underside with a 1/2 inch to

per

5/8 inch per bartack. The front and

bartack

bottom of pockets shall hang free.

10 Join back.

Finished appearance. The center and

side back parts are joined to form a

bi-swing back. The seams shall be

made without puckers, pleats or

distortions.

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business