MIL-DTL-29451B(MC)

Manufacturing requirements - Continued.

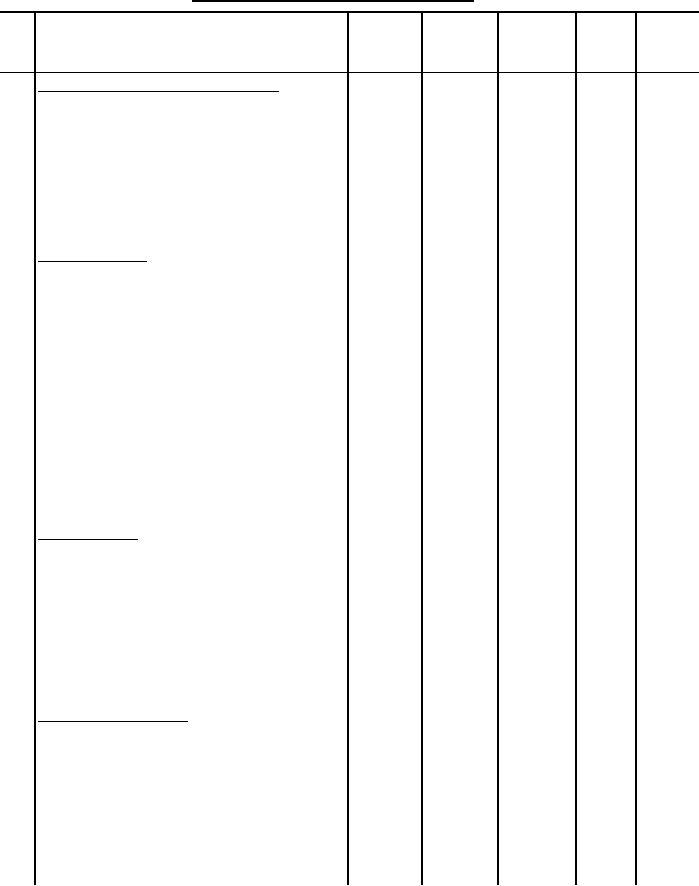

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

28 Join slide fastener to facing.

a. Join the left and right slide

301

SSa-1

10-12

70

70

fastener to the respective facings

with a single row of stitching 1/4

inch from the edge of the chain. The

top of the slide fastener tape shall

be even with the raw edge of the neck

opening and the bottom shall be 3/8

inch from the bottom ± 1/8 inch.

29 Attach collar.

a. The knit collar shall be sewn to

301

SSa-1

10-12

70

70

the neck opening of the basic fabric

from notch to notch with the outside

edges of the front corners turned at

the notch, over and onto the knit and

caught in the stitching with a 3/8

inch seam.

b. The knit collar shall be joined

301

SSa-1

10-12

70

70

to the lining neck opening, with the

lining facing set back 1/4 inch from

the turned in edge of the front. The

finished dimensions of the back

collar shall finish 2-1/2 ± 3/16

inches.

30 Tack armhole.

a. The armhole lining and shell

301

SSa-1

10-12

70

70

shall be joined together across the

or

shoulder with a two inch seam and the

401

underarm seams shall be joined with a

one inch seam.

NOTE: The sleeve or armhole shall

not be distorted or twisted in any

way.

31 Close jacket front.

a. Join the outer shell to the

301

SSa-1

10-12

70

70

lining assembly at the front opening

with a 7/16 inch seam from the folded

edge. When the jacket is closed, the

slide fastener shall not be visible.

b. Raise stitch around the collar on

301

SSak-1

10-12

70

70

the shell with a 1/8 inch seam from

the collar joining seam.

21

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business