MIL-DTL-29451B(MC)

Manufacturing requirements - Continued.

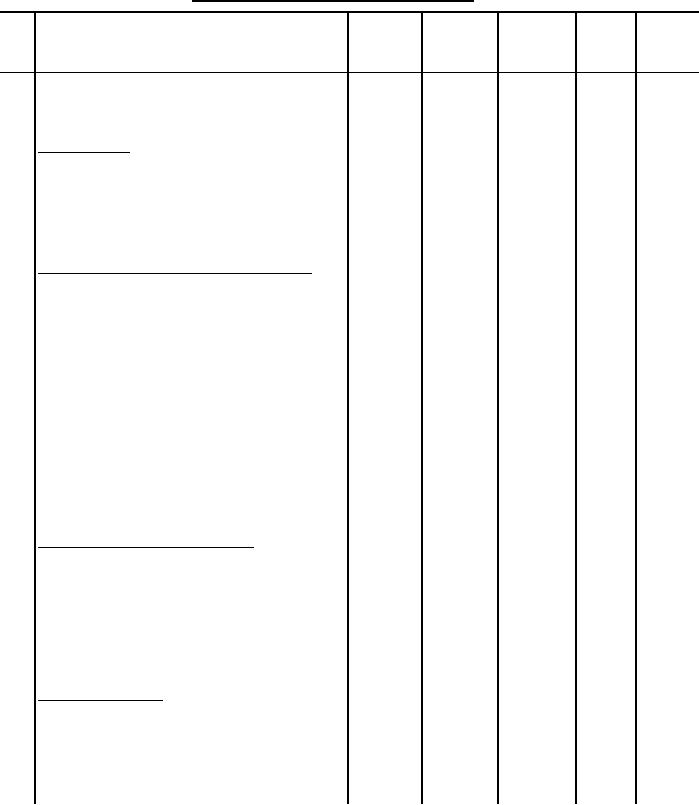

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

b. The finished hanger shall measure

2-1/2 ± 1/4 inches long when measured

along the lower edge of collar.

24 Set sleeves.

a. Join the sleeves to the

301

SSa-1

10-12

70

70

respective armhole with a 3/8 inch

or

seam. The underarm seam of the

401

sleeve shall match the side seam of

the jacket.

25 Join waistband assembly to jacket.

a. Sew one side of the waistband to

301

SSa-1

10-14

70

70

the bottom of the outer shell with a

single row of stitching 3/8 inch from

the edge.

b. Attach the opposite edge of

301

SSa-1

10-14

70

70

waistband to the bottom of the lining

with a single row of stitching 3/8

inch from the edge.

c. With the jacket turned inside

301

SSa-1

10-12

70

70

out, join the outer shell, lining and

or

waistband between the extension

401

pieces with a single row of stitching

3/8 inch from the edge.

26 Join knit cuffs to sleeves.

a. Position knit cuff between sleeve

301

SSa-1

10-12

70

70

and sleeve lining, with seams

or

matching and all raw edges even and

401

stitch together with a 3/8 inch seam.

Stretch knit so that sleeve and

lining fullness is equally

distributed during sewing operation.

27 Make the collar.

a. The collar shall be made of one

ply of knit material, cut in

accordance with the pattern, folded

in half lengthwise and pressed with a

hot steam iron or press.

20

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business