MIL-DTL-28950C(MC)

Manufacturing requirements - Continued.

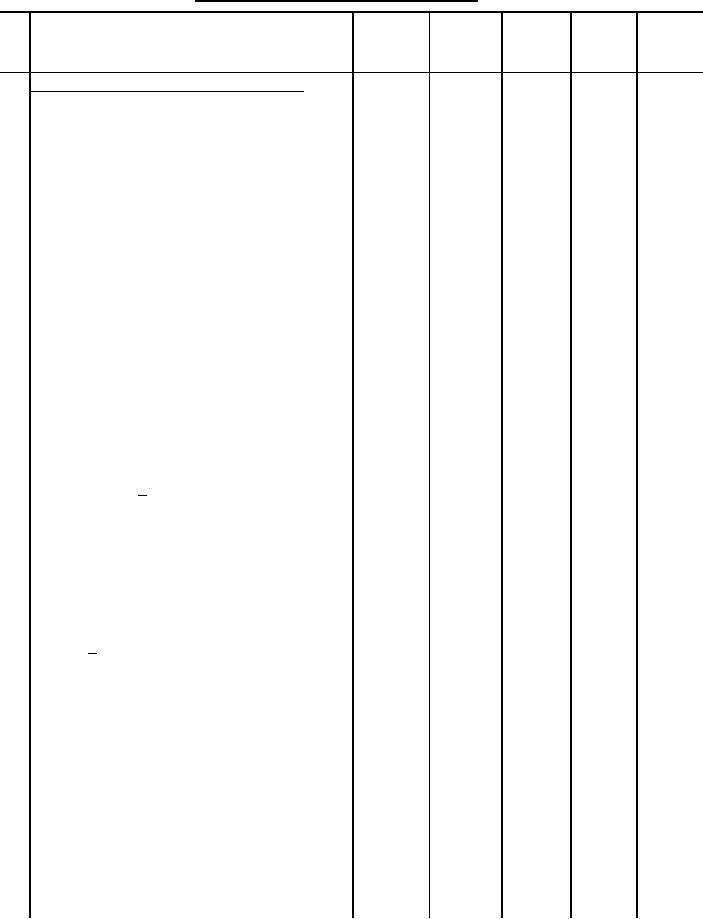

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

6 Make standard belt (see Figure 6).

(cont'd)

e. Turn the end of the belt, working

301

SSc-1

12-16

A

A

out the point. Turn under the upper

(silk)

(silk)

and lower edges of the lining, and

seam the lining to the belt 1/8 inch

from the folded edges of the belt

closing the end and forming a point at

the center of the finished end.

502

EFd-1

10-14

A

A

f. Close the opposite end of the belt

with serge stitching.

or

503

EFd-1

10-14

A

A

g. The finished width of the belt

shall be 1-3/4 (+1/16, -1/8) inches.

The finished length of the belt for

each size coat shall be as shown in

Table II.

h. Make a horizontal straight type

Button-

50 per

A

A

buttonhole, cut 5/8 inch long, midway

hole

button-

between upper and lower finish edges

hole

of the belt to fit a 22-line sewing

(incl.

tack)

button, with the center of the

buttonhole 1 + 1/8 inch from the

buckle end, and with both ends of

buttonhole securely tacked. The

purling of the buttonhole shall be on

the outside of the belt.

i. Mark location for sewing two

22-line sewing hole buttons to lining

side of belt. The center of the

button for the buckle end shall be

3-5/8 + 1/8 inches from the overedge

stitched end of the belt. The button

for the belt fastener shall be

positioned in accordance with mark on

pattern for each size belt. The

buttons shall be securely sewn to the

belt with the end of the stitching

securely tacked.

j. Securely sew one button at each

101

21 per

24/4

mark. The button for the buckle end

button

shall properly engage buttonhole in

buckle end and shall be sewn through

all plies of material. The button for

the belt fastener shall be sewn

through the lining and interlining

only.

16

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business