MIL-DTL-28950C(MC)

Manufacturing requirements - Continued.

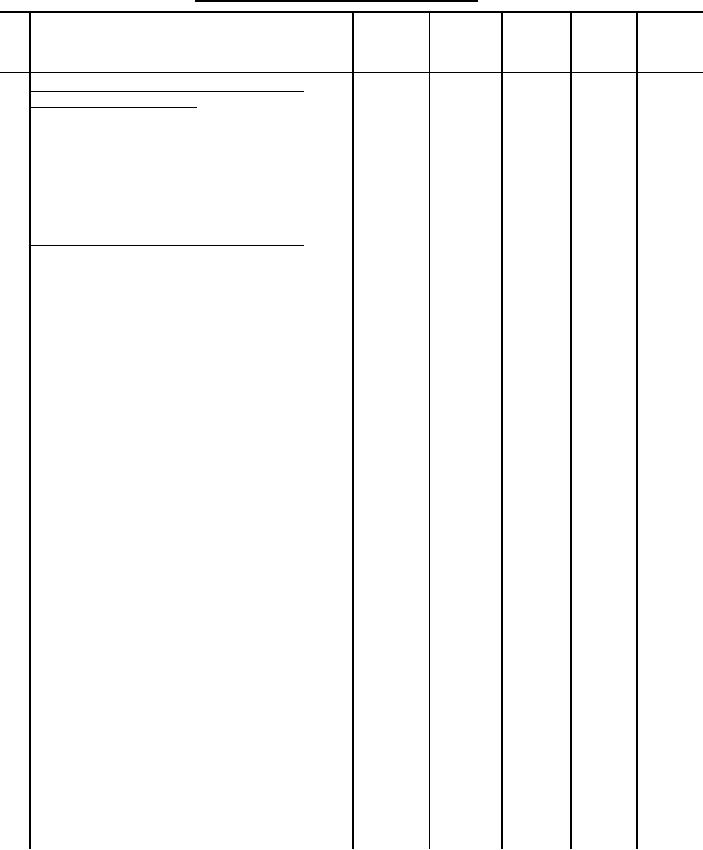

TABLE I.

SEAM/

STCH

STCH

BOB/

NO

OPERATION

TYPE

TYPE

STCH/IN

NDL

LPR

5 Make belt fastener (standard belt

only) (see Figure 6). (cont'd)

c. Turn under one end of the fastener

Button-

50 per

A

A

1-1/2 inches and make a horizontal

hole

button-

straight type buttonhole cut 5/8 inch

hole

long through the center of the turned

(incl.

under portion. the ends of the

tack)

buttonhole shall be securely tacked.

6 Make standard belt (see Figure 6).

Finished appearance. The belt shall

be uniformly stitched and shall finish

smooth and flat without twists,

pleats, puckers, or raw edges. the

pointed end of the belt shall be well

formed with the turned in edges

securely caught in the stitching. The

buttonhole shall be clean cut and well

made.

a. The standard belt shall be made of

one piece of basic material, lined

with rayon lining and interlined with

buckram.

b. Place the interlining material

301

SSa-1

12-16

A

A

between the basic and lining materials

(silk)

(silk)

and seam together uniformly 1/8 inch

from upper and lower edges, with the

raw edges of lining and basic

materials turned in and caught in the

stitching. The stitching shall extend

from one end of belt to approximately

1-1/4 inches from the opposite end.

The lining shall be 1/16 inch back

from the finished edge of belt.

c. Turn lining and basic materials

back at the top and bottom unseamed

edges of the belt and trim the

interlining approximately 1-1/4 inch

back from the end.

d. Fold the end of the basic material

301

SSa-1

12-16

A

A

in half lengthwise to the outside, and

(silk)

(silk)

stitch across the width of the basic

or

or

material 1/8 inch from the end.

A

A

15

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business